Wood Works

MDF (Medium Density Fiberboard)

Features a smooth and homogeneous surface, commonly used in furniture and door panels.

Melamine Faced Chipboard

Moisture-resistant and used in applications that require high durability, such as luxury furniture.

HDF (High Density Fiberboard)

Moisture-resistant and used in applications that require high durability,

such as luxury furniture.

HPL (High Pressure Laminate)

Used in abrasion-resistant surfaces and both interior and exterior decorations.

PVC (Polyvinyl Chloride)

An alternative to wood in indoor and outdoor applications due to

its durability and resistance to moisture and insects.

(Beech Wood)

A hard and durable wood, characterized by its light color and workability, used in premium furniture and flooring.

(Swedish Wood)

Known for its strength and resistance to weather conditions.

(Mahogany)

A premium hardwood, characterized by its dark red color and smooth texture, used in luxury furniture

(Teak Wood)

A hardwood resistant to water and moisture, used in outdoor

furniture due to its high resistance to weather conditions.

(Oak Wood)

Features a smooth and homogeneous surface, commonly used in furniture and door panels.

01

Blueprint Analysis: Analyzing and understanding blueprints provided by the engineering office

02

Cost Estimation: Preparing and providing cost estimates for the project.

03

Sample Approval: Selecting and approving suitable samples for the project.

04

Scheduling: Creating a detailed timeline for the manufacturing and installation process.

05

Manufacturing and Installation: Executing the manufacturing and installation process according to the schedule

06

Supervision: Monitoring and supervising the installation process by supervisors and

07

08

Post-Delivery Services: Providing support and maintenance after project delivery to

ensure customer satisfaction.

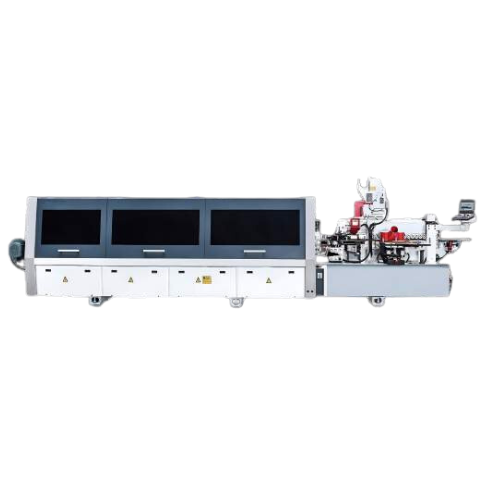

Comprehensive Overview of Key Machinery.

TECHNICAL SPECIFICATIONS .

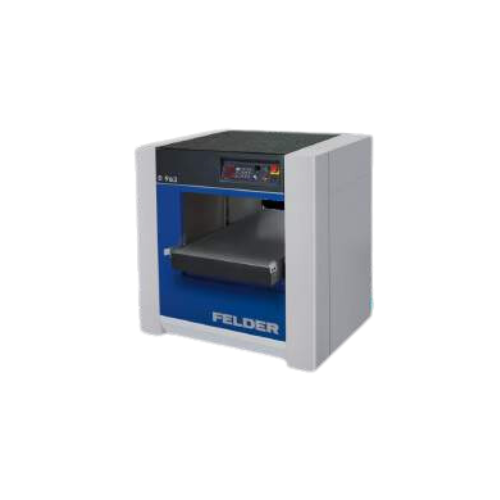

TECHNICAL SPECIFICATIONS .

Sliding table saw MJ1132F makes panel cutting easy and flexible. Powerful saw motor, easy running sliding table, precise guiding board and tilt adjustment. Height of saw blade can be adjusted electrically, main saw blade rotating speed up to 5200rmp and max. cutting length 3100mm.You could use to cut all sorts of panels through simple operation just as your requirements.

TECHNICAL SPECIFICATIONS .

ELECTRICAL SET UP:

• 380 V , 60 HZ , 10 HP

THICKNESS PLANER AND FEED DRIVE

• Thickness Planning Width In 630 MM • Maximum Depth Of Cut IN 8 MM • Electrical Table Height Adjustment For Thickness Table

pre-programmable • Thicknessing height 3-300 mm • Variable speed drive 4–16 m/min

GENERAL

• Extractor Connection Port Diameter 140 Mm 140 mm • Weight , 650 KG ( With Standard Equipment)

TECHNICAL SPECIFICATIONS .

TOTAL THRUST

PLATEN DIMENSIONS

PLATEN THICKNESS

No. of INTERMEDIATE PLATENS

CYLINDERS

CYLINDERS DIAMETER

CYLINDERS STROKE

MAX. PRESS OPENING (SINGLE DAYLIGHT) HYDRAULIC POWER PACK THERMAL POWER OF ELECTRIC BOILER

TECHNICAL SPECIFICATIONS .

• Multi-functional CNC drilling machine is able to drill from 6 sides and top&bottom grooving, simple routing meets different process requests and gives batch-size-one production max flexibility; • Machine is configured with one top and one bottom drilling blocks&3.5kw main spindle, Additional independent saw blade. • Software is open port, support most formats in market. • Standard with side outfeed conveyor table, selectable to outfeed from front and back.

TECHNICAL SPECIFICATIONS .

SPECIFICATIONS:

• Surface Planning Width : 510 mm • Total Planer Table Length : 2700 mm • In feed planer table length: 1350 • Maximum Depth Of Cut : 8mm • Professional Fence place anodized 170 x 1300 mm, tilt able 90°-45° • Planner Guard Euro Standard • Both cast iron tables with easy height adjustment • Silent power spiral planer

GENERAL

• Working Height In 890 Mm

• Extractor Connection Port Diameter : 140 Mm

• Weight: 800 KG (With Standard equipment)

ELECTRICAL SETUP

• 3ph, 380v , 60HZ, 7.5 HP

PLANERS FOR FELDER, A SOLUTION TO SUIT EVERY BUDGET:

• The product advantages for of the fielder A 951 L

• Silent system cutter block with self-setting blades for optimum

planning result.

• Space saving professional planer fence with maximum ease of use.

• Solid cast iron components used for smoothest operation

• Solid asymmetrical planer tables with total length of 2700 mm

TECHNICAL SPECIFICATIONS .

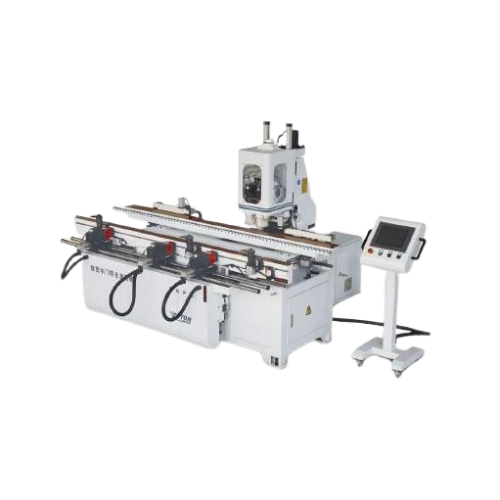

• Working length: 1800-2400mm

• Working width: 600-1100mm

• Working thickness: 30-60mm

• Hinge motor power: 4×0.4Kw

• Lock-slot motor power: 3.7Kw

• Lock sidestep motor power: 0.4Kw

• Lock-hole motor power: 2*1.5Kw

• Max moving speed of tool: 8m/min

• Overall size: 2740*2270*1620mm • Wooden case size: 2800*2290*2060mm

• Weight: 1800kg

• Voltage: 380V, 60HZ, 3phase